Equipment Trade-In

IN ADDITION TO PROVIDING USED EQUIPMENT AND NEW EQUIPMENT, WE ALSO OFFER TRADE-IN SERVICES IN SOME INSTANCES.

We will do whatever is necessary to replace old equipment with newer, safer, and lower cost of ownership equipment.

GIVE US A CALL AT 800-837-4427 OR USE OUR CONVENIENT ONLINE FORM, AS WE ARE ALWAYS LOOKING FOR EQUIPMENT WE CAN TAKE ON TRADE!

Ready to Get Started

ENERGY SAVINGS

Through our innovative design and manufacturing process, we provide an oven that provides unparalleled levels of efficiency compared to other ovens. This efficiency is achieved through materials used for thermal insulation, low-emission glass, proprietary combustion chamber design, and motorized shutter on the chimney that better retains the heat, making better use of the fuel resources.

PRODUCTIVITY

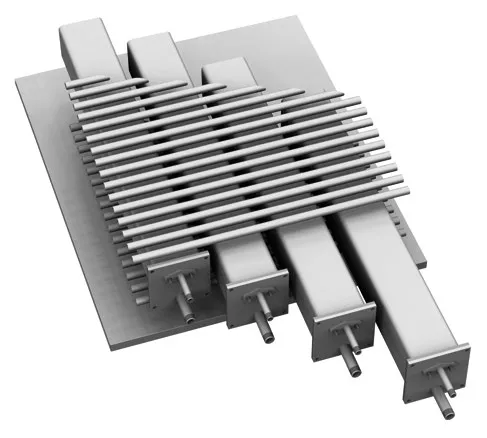

When we take into account the exceptional reliability of the Polin Steam Tube Ovens along with the rapid recovery and quick start-up, the baking system allows for significantly increased production compared to competing models. These characteristics allow bakers to usually increase their daily production by up to 25% because they are not waiting on the oven. This results in a much improved ROI.

RAPID RECOVERY

We succeeded in designing and manufacturing an oven with a reduced quantity of installed thermal power (up to 40% less in comparison to some competitors) while outpacing the temperature recovery speed. This all originates back to the efficiency of the design and is a testament to the continual goal of ensuring that wasted energy is kept at the absolute minimum.

RELIABILITY

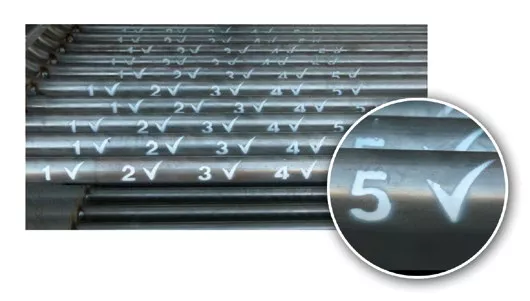

Improvements in savings and ROI are not only results of low-consumption, but perhaps more important is the service life and maintenance time of the oven. For steam tube ovens specifically, the point of final failure is almost always the tubes. Over time, pressure and heat will deteriorate tubes that are manufactured with sub-par materials and/or manufacturing processes. For our ovens, Polin only uses the highest quality materials and optimizes the routes and bends of the tubes in order to achieve the minimum possible thermal stress. In addition, most manufacturers pressure test the tubes as a part of a sample size rather than every tube individually to save production costs. At Polin, we pressure test every tube at least five separate times to effectively eliminate the possibility of tube failure. The tubes are tested at pressures exceeding 10,300 psi when standard operating pressure is only around 1,250 psi. This is the only way to truly guarantee a service life that exceeds any of our competitors.

EASY MAINTENANCE

Another important aspect to consider is serviceability of the critical oven components. Being that utility water always creates a tough environment for various materials and metals, this is compounded by adding the element of heat to the equation. In the ovens, the steam generators especially take the brunt of this. We designed the ovens so that the generators are easily accessible and removable from the front.

CONNECTIVITY

The Polin TV Synt line of ovens is also available with the Polin BakeApp LAN or WLAN remote control. This allows the client to monitor and manage one or more ovens connected by a network (either same location or multiple locations) through an internet connection. They can be accessed through any browser running IOS, Windows or Android whether on a PC, tablet, or smartphone. This allows you to upload/download baking programs, change settings, real-time diagnosis and consumption analysis, and also check operator efficiency and productivity.