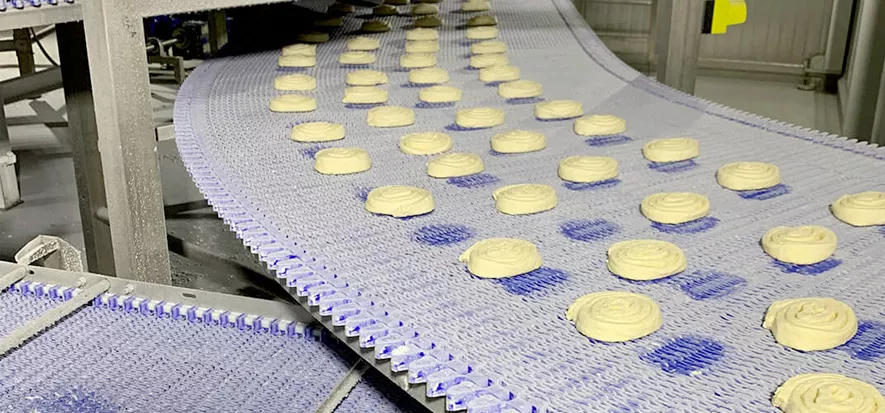

Spirals Line

Spiral Systems for Thermic Treatments

Spiral systems for thermic treatment in food production are versatile and reliable and among the most technologically-advanced systems on the market.

Why spirals? Spirals maximize production performance during the leavening process, while also minimizing your production footprint. Efficient performance increases energy savings and ensures optimal sanitation and maintenance processes.

PROOFING

Our spirals are designed to maintain food’s organoleptic qualities during the leavening processes, ensuring total control of humidity, temperature and air flow levels. In particular, the VK31 belt’s smooth-sliding performance allows a more natural leavening method.

COOLING

Our spiral system is advantageous for cooling processes, both for the cooling in the production environment, and in the cold room by means of forced and filtered air through the insertion of chillers and ATUs. Our solutions guarantee superior performance and allow maximum control of fundamental parameters, such as temperature and air flow.

FREEZING

This state-of-the-art freezing systems allow maximum control of product freezing. Storage of product can be prolonged by placement in an insulated room specially designed to optimize the air flows created by evaporators.

VK31 SPIRALS

Our patented construction of spirals with external drives guarantee low coefficients of friction and wear, attaining consistent, quality production in a highly-sanitized facility.

Each spiral is designed from the outset to customer specifications for leavening, cooling and freezing. Product can be transported in bulk, packaging or special containers

FEATURES

MATERIALS AND SLIDING – The VK31 tape provides options for various products. The belt runs on a plastic anti-friction profile fixed on stainless steel guides.

STRUCTURE – The VK31 spiral structure stainless steel and equipped with adjustable feet for stability and structural integrity. Designed for easy maintenance and cleaning, the spiral was developed to minimize the production footprint. To maintain consistent air flow, a temperature control unit monitors conditions from the center of the spiral. This system can be used for leavening, cooling and freezing processes.

SINGLE-MOTOR DRIVE – The drive unit is a single motor with stainless steel shafts, adjustable steel supports and plastic gearwheels to transmit motion to the chain.

SENSORS – A capacitive sensor is on every level of the spiral to detect any problems and allow quick response to potential malfunction or system failure. A product height control sensor, installed at the entrance to the spiral, is available upon request.

DRUM SPIRALS

The drum spirals consist of a commercial conveyor belt equipped with a cylindrical, drum-shaped towing system. This solution is designed for maximum performance with minimum use of space. Food can be transported in bulk, packaged or in special containers.

Sturdy and durable, our drum spirals can be used for continuous work cycles and in extreme conditions including temperature, speed and product load.

FEATURES

FUNCTION – The central drum transfers dynamic friction force generated by the belt from dissipative to conservative force.

STRUCTURE – The spiral structure surrounds the drum, which supports the spiral curvature and the belt, which is wound around the drum cylinder. Above the spiral curves, a high-density, low-coefficient plastic material guides product into it.

REQUEST A QUICK QUOTE

WE ARE HERE TO HELP

Contact our equipment solution experts today!